Westside Door offers EL & EL Wood Products® to Southern California Homeowners, Developers, Architects and Designers.

EL & EL Wood Products® specializes in exceptionally fine wood and urethane Mouldings, interior and exterior doors, carvings, columns & mantels. The brand is renowned for its moulding and millwork products and is pre-eminent across California, Nevada and Arizona.

EL & EL Wood Products® Interior Mouldings and Trims, Base Mouldings, Crown Mouldings, Baseboards, Flexible Mouldings, Casings and more are available at WESTSIDE DOOR in West Los Angeles, an EL & EL Wood Products® Authorized Dealer serving the West Los Angeles, Brentwood, Bel Air, Santa Monica, Malibu, Pacific Palisades, South Bay, Hermosa Beach, Manhattan Beach, Redondo Beach, Rancho Palos Verdes, Palos Verdes, Orange County, Laguna Beach, Irvine, Huntington Beach, Newport Beach and surrounding Southern California.

Westside Door Since 1971 is an Authorized EL & EL Wood Products® Dealer in West Los Angeles. Serving Los Angeles County, Orange County, Riverside County, Inland County and all of Southern California Area.

We Welcome Home Owners, Builders, Interior Designers, Architects and General Contracts Call us: (310) 478-0311 or Email at: customer.service@westsidedoor.com

EL & EL Wood Products® Base Mouldings, Crown Mouldings, Baseboards, Casings – Available at Westside Door – The Best Little Doorhouse In Town® Since 1971 – Call: 310-478-0311

EL & EL Wood Products® Base Mouldings, Crown Mouldings, Baseboards, Flexible Mouldings, Casings and more are available at Westside Door an EL & EL Wood Products® Authorized Dealer serving West Los Angeles, Orange County, Southern California. Call us: (310) 478-0311

EL & EL Wood Products® Mouldings are used to enrich rooms and spaces by lending their decorative patterns to decorate doorways, windows, ceilings, walls, and other surfaces. EL & EL Wood Products® Mouldings can be regarded as an extension of one’s creative ideas or concepts giving an unlimited amount of uses to each and every item. Each property owner’s ideas are unique and personal and can be an expression of one’s own taste and style that lend a home or establishment a special look and feel.

STORAGE, HANDLING, AND PREPARATION OF ALL MOULDINGS AND S4S BOARDS

Prior to installation, it is important to acclimate your moulding and trim products by storing them in the installation space for at least 3 days. Wood and wood based products can expand and contract depending on internal and external environmental moisture levels. For best results, be sure to store products in a dry location and transport only if fully protected from water. Keep products clean from dirt and debris and finish according to paint and stain manufacturers’ recommendations.

1 – ARCHITRAVES

In classical architecture, it described the main beam resting on the tops of the columns. Today it is often used as a decorative moulding for ornamentation or finishing at the top of windows and doors.

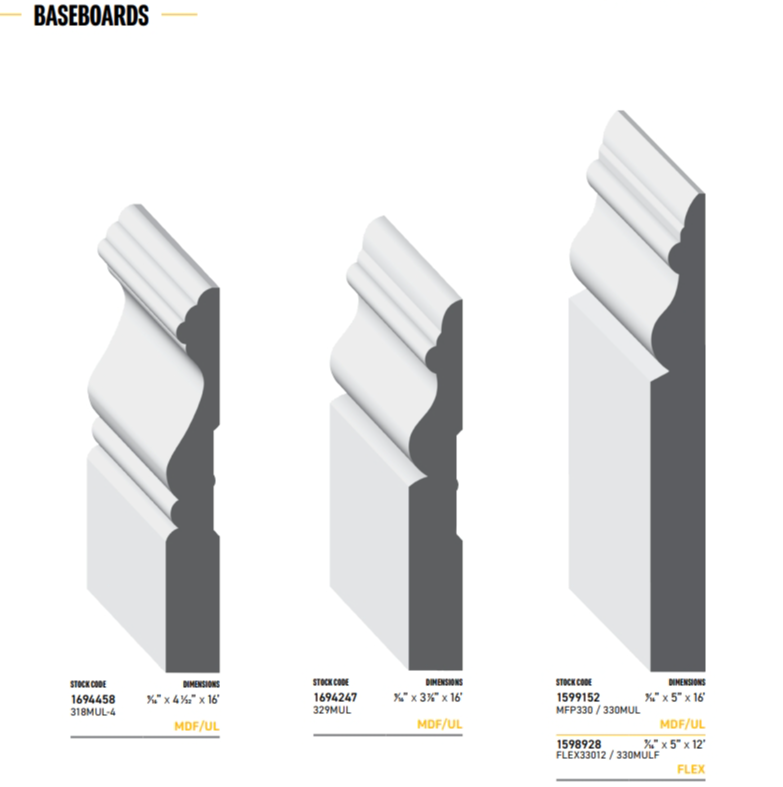

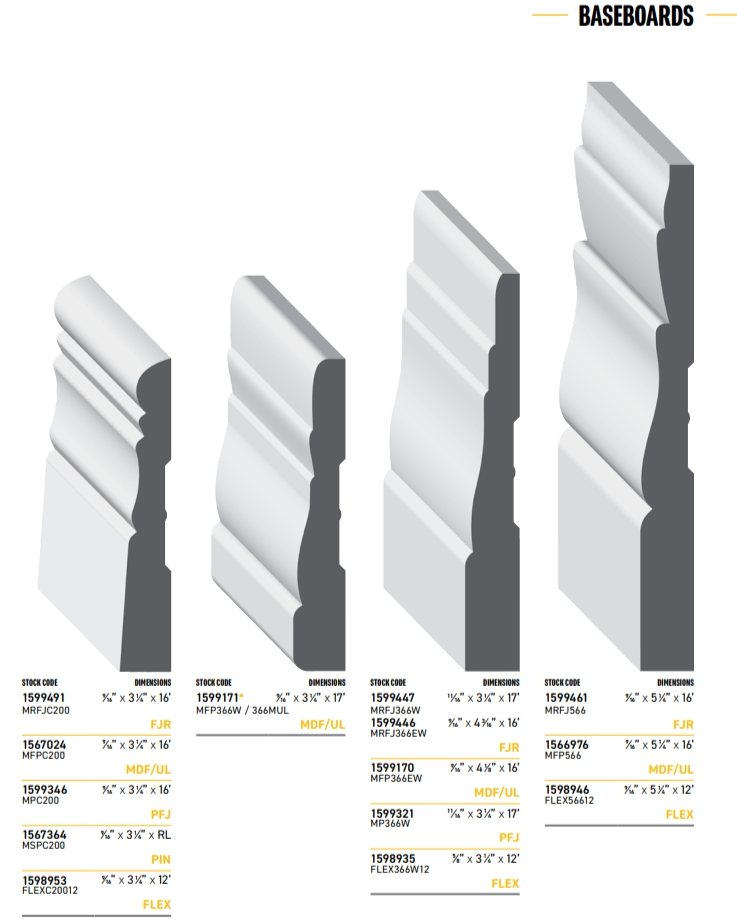

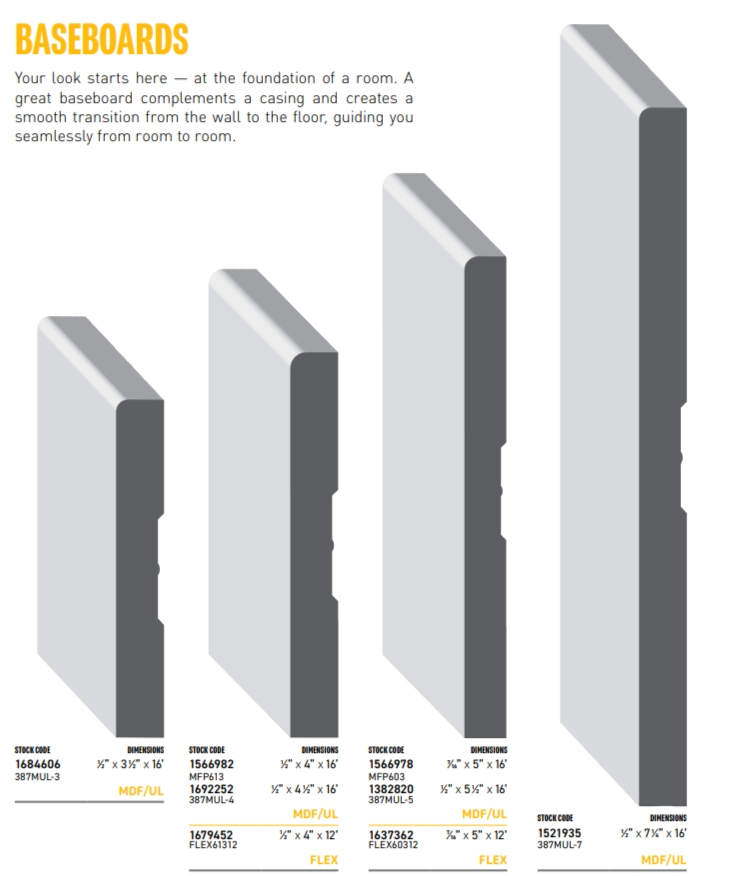

2 – BASEBOARDS

Baseboards are placed along the wall at the floor. They should be chosen to work in harmony with your casings to finish and tie the room together. Baseboards are usually thinner than the casing.

3 – BUILD-UPS

Combining two or more moulding profiles to create a new or custom look. Also called stacking, build-ups make it easy to create the look of custom made trimwork without the high cost.

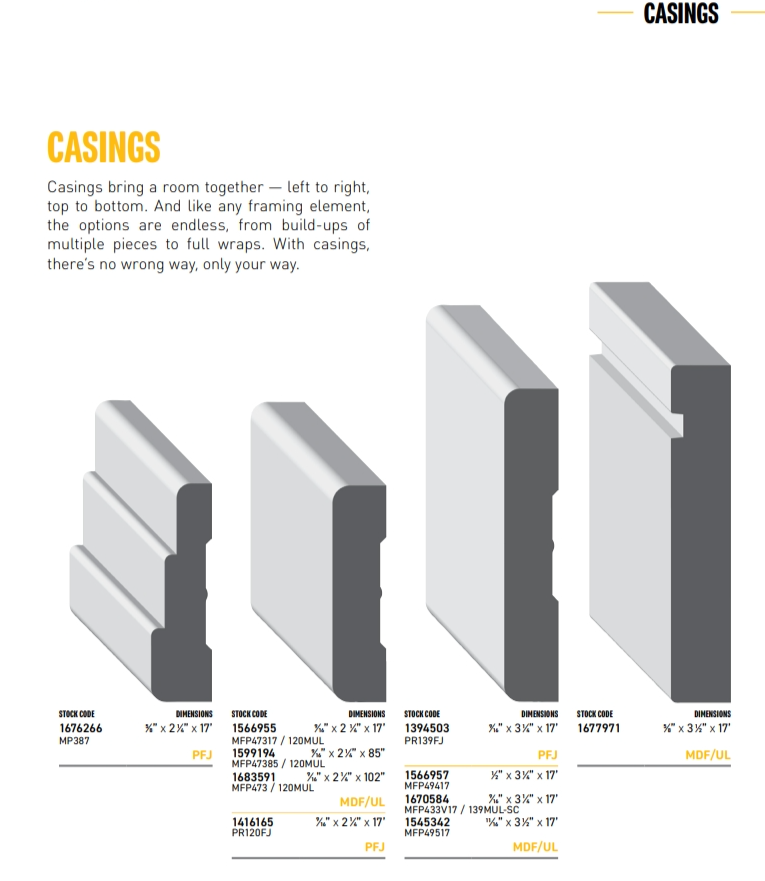

4 – CASINGS

Casings define the overall character of a room and are often the most visible part of the trim. They are used primarily to cover the gap between drywall and the door or window frame. Casings are generatlly thicker than the base mouldings.

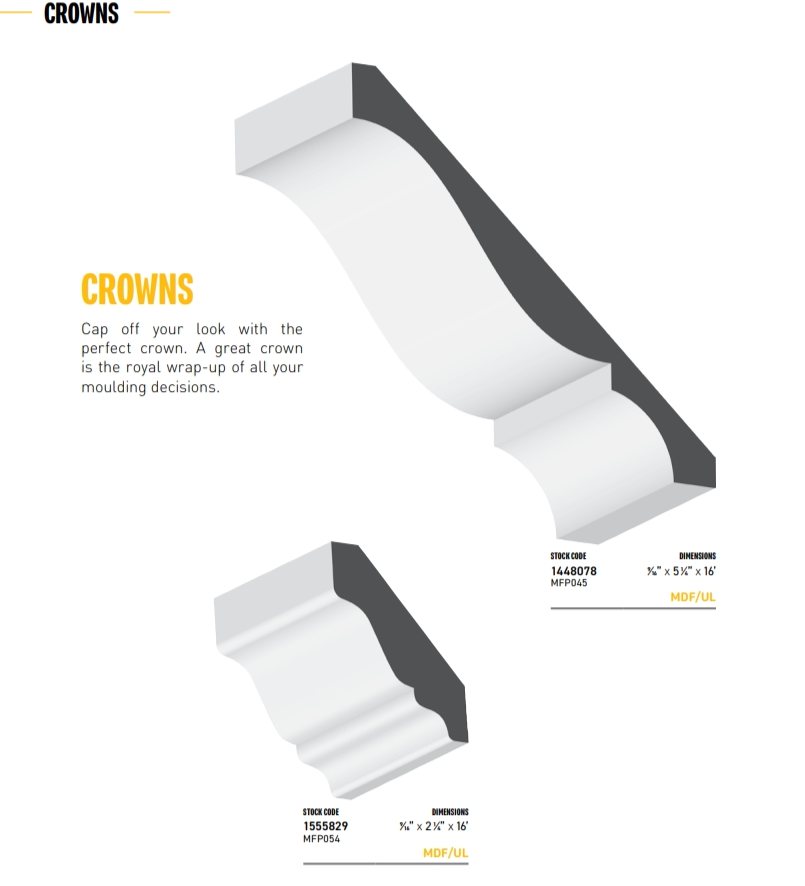

5 – CROWNS

Crowns are placed along the wall at the ceiling. They come in a wide range of patterns and sizes. Crowns soften the transition from wall to ceiling while adding a distinctive look and charm to your room.

6 -FINISH BOARDS

Finish Boards come in either S4S (Surfaced 4 Sides) or S3S (Surfaced 3 Sides) and are used for a multitude of purposes including shelving, window liner, bases, casing, etc.

7 – PANEL MOULDS

Panel Moulds are used to frame wall paneling and add an accent to your walls. Often used in furniture construction.

8 – RAKE MOULDS

Rakes are often used as crowns. In fact they are sometimes called “solid crowns.”

9 WAINSCOT

Trimwork installed in the area below a chair rail. Numerous options are available including raised panel, shadow box, and beaded. Combined with a chair rail and baseboard, Wainscoting creates a dramatic look to any room.

10 – WINDOW STOOL

Also called window sill, a Window Stool is the surface installed below the sash of a window. Trim installed under window stool creates a distinctive look and adds a decorative touch.

SUBMIT ORDERS to: customer.service@westsidedoor.com

Working with Moulding?

Here are the right tools for when you are working with EL & EL Wood Products® Base Mouldings, Crown Mouldings, Baseboards, Flexible Mouldings, Casings and More:

- Quality Miter

- Box Nail Set

- Tape Measure

- Putty Stick

- Hammer

- Coping Saw

- Finishing Nails

Estimating

To figure out how much moulding is needed, carefully measure the length of each wall where your moulding will be installed. Record the length of each piece and round up to the next foot. Total the lineal footage needed. Add 5-10% for cutting and trimming and order the number of pieces needed in the available length of the material selected.

Mitering

Most miter joints are 45° angles. The moulding is either placed flat on the bottom of the miter box or against the back, depending on how the moulding is to be used. Each of the two mitered members are trimmed at opposite 4 angles. When fitted together, the two pieces will form a 90° angle. For tight mitered joints, nail and glue, then countersink the nails.

Splicing

Occasionally it may be necessary to splice mouldings together on a long wall. To do this, position the pieces in the wall miter box as if the back of the miter box were the wall. Miter the joining ends at a 45° angle.

This will allow one piece to overlap the other, making a scarf joint. Make the joint where the two pieces can be nailed into a solid piece of lumber, such as a stud, top plate or bottom plate. Gluing the joint will assure you that the joint will stay closed.

Coping

Position the piece in the miter box as if the back of the miter box were the wall when cutting the miter. Trim at a 45° angle. The resulting cut exposes the profile of the moulding, which serves as a guide line for the coping saw.

Following this profile with the coping saw at a right angle with the face of the moulding. This cut results in a duplication for the moulding pattern which will then fit tightly against the face of the adjoining moulding.

Fastening

Power tools should be set at 100 to 110 PSI to compensate for MDF’s dense surface. A little glue and small diameter nails assure tight joints. Putty the holes, sand to blend and then paint.

Factory primed mouldings permit the use of both water-based and solvent-based finish coat applications. Avoid using any catalyzed paints or varnishes. A second prime coat or scuff sanding is optional. Apply the finish coats with brush, roller or spray using flat, semi-gloss, enamel or lacquer; whatever suits your requirements.

Jigs

Many projects require “picture framing” techniques of extreme accuracy. A jig in the mold in which frames are made more rapidly uniformly. The inside dimensions of the jig equal the outside dimensions of the frame. The jig consists of stock lumber pieces nailed to any flat surfaces. Blocks can be used where necessary to straighten mouldings against the side of the jig.

Baseboard Moulding

EL & EL Wood Products® Baseboards. SUBMIT ORDERS to: customer.service@westsidedoor.com

Baseboards are used where the wall joins the floor. They are excellent when turned upside-down and used with Crown Mouldings to form larger crown details and with the addition of Panel Mouldings, baseboards can be made taller creating a larger baseboard.

Casing Moulding

Casing Moulding. SUBMIT ORDERS to: customer.service@westsidedoor.com

Casing moulding can be used as door casing and window casing, as trim around the window or door. Casings can also be used as large chair rails, or upper horizontal linear banding around rooms.

Crown Moulding

Crowns are placed along the wall at the ceiling. They come in a wide range of patterns and sizes. Crowns soften the transition from wall to ceiling while adding a distinctive look and charm to your room.

EL & EL Wood Products® Crown Moulding. SUBMIT ORDERS to: customer.service@westsidedoor.com

Crown and Corner Mouldings are used where the wall joins the ceiling. Crown mouldings can be used alone or built up using lineal mouldings, such as baseboards, casings, chair rails or panel mouldings, to create larger details and unique designs.

EL & EL Wood Products® specializes in exceptionally fine wood and urethane Mouldings, interior and exterior doors, carvings, columns & mantels.

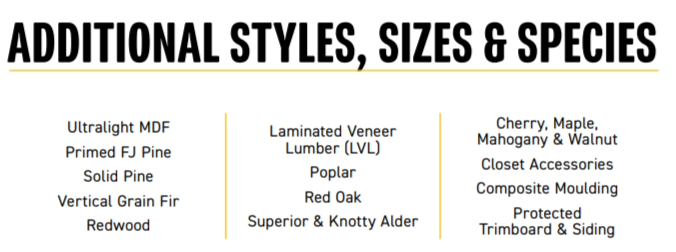

About METRIE® EL & EL Wood Products

In 2022, EL & EL Wood Products was acquired by METRIE® in their largest-ever acquisition. Similar to EL & EL, METRIE® is family-owned and a long-time market leader in the moulding, millwork, and the door business in Canada and across the US, with one notable exception — California. The region EL & EL Wood Products has served with distinction for 55 years was the missing piece of the customer service puzzle for Metrie. So, the fit was perfect!

Today, METRIE® EL & EL Wood Products are STILL the same people that care greatly for each and every customer, whom they consider their extended family. They have just adopted a new name, METRIE® EL & EL. They say that “we are better, together,” and there is no doubt METRIE® benefits from the skills, entrepreneurial spirit, and excellent customer service provided by the teams in California, Nevada, and Arizona. In turn, EL & EL gets to work with North America’s largest manufacturer and distributor of moulding, and continue to build their customer solutions. METRIE® is definitely the industry leader in all of North America now.

To learn more about EL & EL Wood Products®, you can reach out to Westside Door – your Authorized EL & EL Wood Products® Dealer in West Los Angeles, Southern California. Also serving Orange County, South Bay, Beverly Hills, Malibu, West Los Angeles and all of Southern California.

Westside Door – The Best Little Doorhouse In Town® Since 1971 – Southern California Authorized EL & EL Wood Products® Dealer in West Los Angeles

We are located in West Los Angeles., on Sepulveda Blvd., between Pico and Olympic, one block east of the 405 Freeway.

We’ve been specializing in doors, windows, mouldings, skylights, and hardware since 1971.

Address:

Westside Door & Moulding

2326 South Sepulveda Blvd.

West Los Angeles, CA 90064

Monday–Friday 7:00am-4:00pm

Sales

Phone: (310) 478-0311

Fax: (310) 478-0314